Explore the latest in Wireless Power Transmission (WPT) technology for consumer electronics, healthcare, and electric vehicles. Download our expert guide to learn about high-power inductive coupling, advanced methods, and key applications in WPT. Ideal for specialists seeking detailed insights.

Installing high-power electronic products in sealed enclosures presents unique challenges in terms of thermal management. This article discusses how premium power conversion products, such as the TDS-3300 and TDX-3300, can be mounted in sealed enclosures using an optimized approach for heat dissipation. The importance of sealed enclosures is highlighted, along with the use of heat sinks and thermal pads, and precise methods for calculating heat sink size and thermal resistance.

In industrial applications, sealed enclosures are essential to protect electronic systems from environmental factors such as moisture, dust, and contaminants. However, these enclosures also pose a significant challenge: effective heat dissipation. High-power conversion products like the TDS-3300, TDX-3300, ODS-3000, and ODX-3000 generate substantial amounts of heat, which, if not properly managed, can compromise performance and reduce the product’s lifespan.

This article focuses on how to efficiently manage heat in sealed enclosures using heat sinks and thermal pads. Proper thermal planning is key to ensuring that the equipment operates within a safe temperature range without sacrificing the integrity of the sealed enclosure.

Importance of Sealed Enclosures

Sealed enclosures not only protect electronic components from external elements but also allow their use in harsh environments such as factories, outdoor settings, or marine applications. However, this isolation creates a challenge: heat buildup in a confined space. Without adequate airflow, products like the TDS-3300 and TDX-3300, originally designed to be cooled by internal fans, can overheat.

Thermal management within these enclosures is critical to avoid system failures. A well-designed enclosure, along with the installation of heat sinks, ensures that the generated heat is efficiently evacuated without compromising the enclosure’s seal.

Enclosure Dimensions and Design

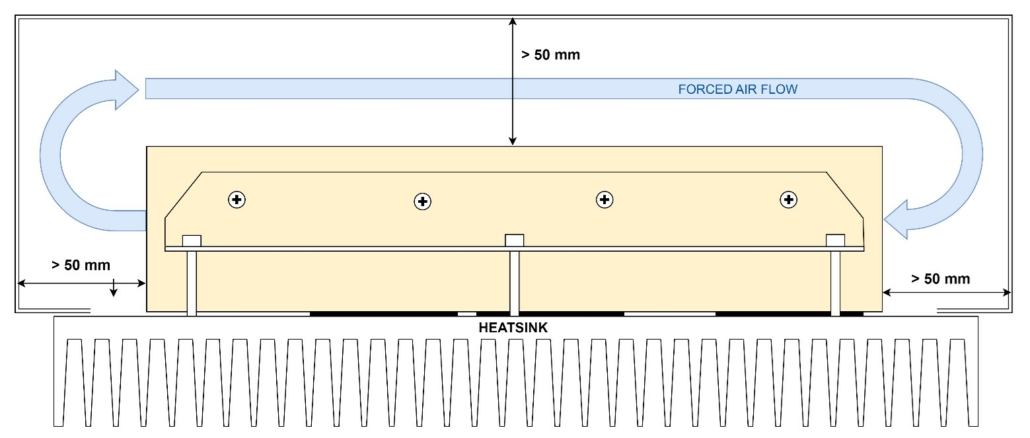

It is crucial that the sealed enclosure is large enough to allow proper air circulation around the device. It has been determined that a minimum space of 50 mm on each side of the product allows hot air to disperse evenly, minimizing heat buildup in critical areas.

The design of sealed enclosures must consider not only protection from external agents but also how to manage the heat generated internally. This is where heat sinks play a key role, channeling heat outside the enclosure while maintaining its airtight integrity.

Thermal Coupling with the Heat Sink

One of the most critical factors in thermal management is proper coupling between the heat sink and the product. To ensure efficient heat transfer, it is recommended to use 1 mm thick thermal pads placed strategically on the hottest surfaces of the device. These pads allow the heat sink to conduct heat out of the enclosure without requiring active airflow inside, maintaining the sealed enclosure.

Positioning of Thermal Pads

For products like the TDS-3300 or TDX-3300, thermal pads, such as the Bergquist GPVOUS-0.04-01 or equivalents, approximately 100 x 100 x 1 mm, should be placed where the internal heat sinks are closest to the outer casing. This coupling ensures efficient heat conduction from the inside to the outside of the system, where the heat sink can dissipate the heat.

Embark on a journey into the future of power supply technology with Premium PSU’s cutting-edge whitepaper. Gain profound insights into the world of wide band-gap semiconductors and their revolutionary impact on power conversion systems.

Our RDI team continously works to improve the design and functionality of our devices, so testing processes are part of day-to-day activities. Download and read this new technical article, where we offer you tips to use and maintain 3ph DC/AC inverters and methods to control induction motors.

Designing increasingly perfect energy solutions is our priority. Gallium nitride or GaN technology allows operation at much higher voltages, frequencies and temperatures than conventional silicon. This allows achieving increasingly compact and powerful systems. Read more

In our new #PremiumTech series today we show you the advantages of using SiC MOSFETs in power design, what challenges it entails and how it is crucial if we seek to maximize efficiency. SiC technology allows us to achieve very high levels of power density and performance, in a stable and compact way. Read more

In our latest whitepaper, we provide a comprehensive overview of the elements that cause electromagnetic interference (EMI) and details which are the most innovative technical solutions to reduce emissions.

At Premium PSU we always strive for designs that make a difference. Investing in technology and know-how is what sets us apart when developing compact and reliable high-power devices. In this article, we share our 15-year experience using SiC technology and what differences it makes compared to other technologies used in the market.

How does the waveform of a DC/AC inverter affect its performance?

We tell you all about it in this white paper, the first of a series of Inverter Tips we are releasing.

At Premium PSU, we are specialists in designing and manufacturing power conversion systems for the industrial market. Our product range includes high reliability power supplies from 50W to 72kW.

PREMIUM PSU

C/ Dolors Aleu, 19-21, 2nd Floor

08908 – Hospitalet de Llobregat

Barcelona-SPAIN

t.+34 93 223 26 85