Comparison of Isolated and Non-Isolated Converters

Introduction to Isolation

In power conversion systems, galvanic isolation refers to the absence of a direct conduction path between different sections of the circuit. This isolation barrier between input and output stages is crucial for proper circuit functioning and serves as a safety measure.

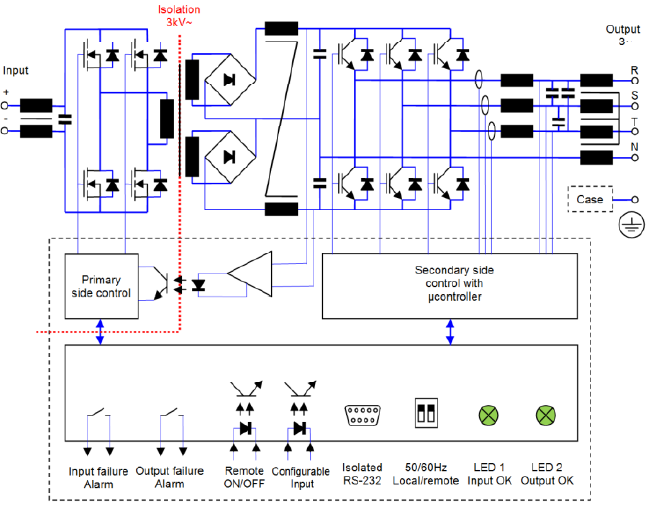

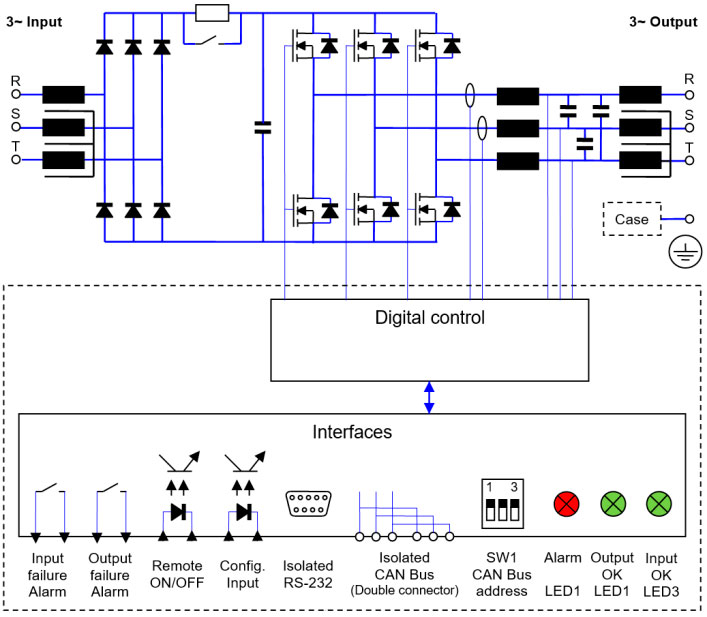

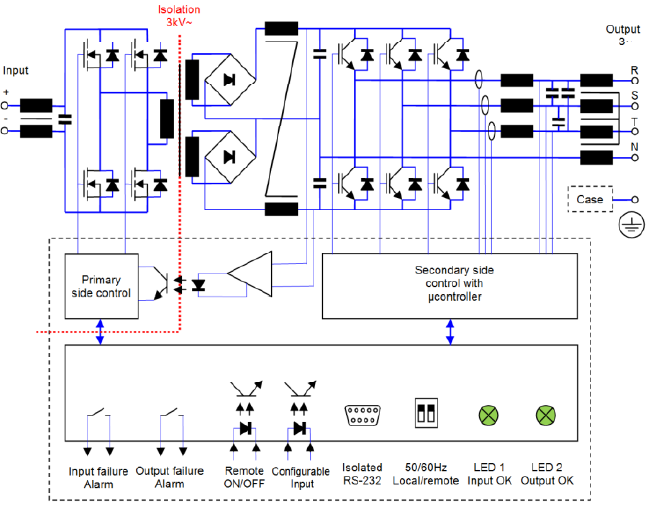

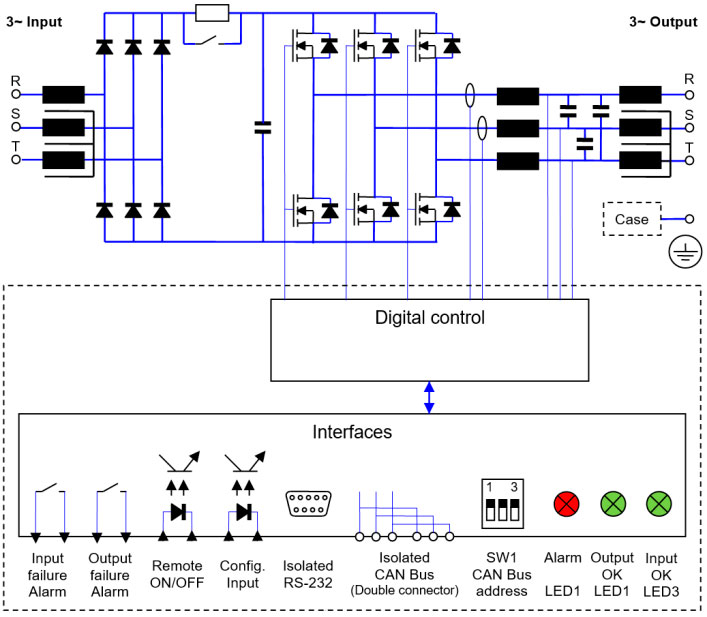

Isolated converters feature separate grounds for input and output stages, while non-isolated converters share a common ground, enabling direct current flow between the two sides. The inclusion of a transformer in isolated converters facilitates isolation by transferring power through electromagnetic energy, albeit with some associated efficiency loss that can be mitigated with a well-designed transformer.

To transmit signals across the isolation barrier, especially for regulated devices requiring feedback, maintaining isolation for these signals is crucial. Miniature signal transformers can be used for AC signals, while optocouplers are suitable for DC signals, ensuring proper isolation.

Isolation is achieved through electrical insulation, either by spacing conductors with air or using non-conductive materials like tape. The effectiveness of this isolation is typically measured by voltage thresholds, with exceeding these thresholds risking isolation breakdown.

Reasons for Isolation

Isolated converters play a vital role in meeting safety standards, particularly when dealing with high and potentially hazardous voltages, such as those from AC/DC converters connected to AC mains. The isolation effectively separates the output from any hazardous voltages present on the input, ensuring compliance with safety regulations.

The appropriate level of insulation, determined by safety standards, is crucial for prioritizing safety. Insulation grades, including functional, basic, supplementary, and reinforced, provide varying degrees of protection against electric shock, with reinforced insulation offering the highest level of protection.

There are four primary grades of isolation:

- Operational Insulation: Also known as functional insulation, this serves operational purposes without providing protection against shocks.

- Basic Insulation: Consisting of one layer, it provides protection against shocks.

- Supplementary Insulation: Adds an extra layer to basic insulation, enhancing redundancy.

- Reinforced Insulation: Offers double the protection of basic insulation with a single barrier.

Isolated supplies are beneficial in preventing ground loops and noise interference due to their separate grounding. This separation is advantageous for circuits susceptible to noise, as it isolates the ground from potential sources of interference.

Isolated converters also feature floating outputs, unlike non-isolated converters with predetermined voltage between output terminals. Floating outputs do not have a specific or fixed voltage relative to other circuit nodes, allowing flexibility in level shifting and circuit configuration. Connections between terminals can alter or reverse outputs compared to other circuit points, enabling versatile applications.

Reasons for Non-Isolation

Despite the advantages of isolation, there are compelling reasons to consider non-isolated converters, such as cost, size, and performance.

- Cost Reduction: Non-isolated converters are generally less expensive due to the use of off-the-shelf inductors instead of custom-made transformers, which are costlier. Isolated converters may also require additional components like optocouplers, further increasing costs.

- Size Efficiency: Non-isolated converters are typically more compact because they use inductors instead of transformers and operate at higher switching frequencies, resulting in smaller magnetic components and capacitors.

- Enhanced Efficiency: Non-isolated converters often exhibit better efficiency and regulation due to fewer components and the absence of a transformer, allowing for more direct monitoring and precise regulation of the output.

Applications

Non-isolated converters are commonly used in Point of Load (POL) settings to convert high voltage to lower voltage, often in industrial settings where the power supply is enclosed in well-insulated cases.

Isolated converters are essential in medical, military, and heavy industrial settings where strict isolation standards are mandatory for safety compliance. Industries requiring high voltages necessitate power supplies with robust isolation to minimize risks of electrical hazards.

In summary, choosing between isolated and non-isolated converters depends on specific application requirements, balancing factors like cost, size, efficiency, and safety considerations dictated by the end-use environment. Isolated converters are crucial for applications demanding stringent safety compliance, while non-isolated converters offer cost-effective and compact solutions for less hazardous environments. Understanding the difference between isolated and non-isolated converters is essential, particularly in the case of isolated DC/DC converters.