SiC Technology: 15 years at the cutting edge

At Premium PSU we always strive for designs that make a difference. Investing in technology and know-how is what sets us apart when developing compact and reliable high-power devices. In this article, we share our 15-year experience using SiC technology and what differences it makes compared to other technologies used in the market.

The effect SiC technology has on the performance and size of our products is what makes it essential in our designs.

Almost 15 years have gone by, but we perfectly remember an email asking about a 1200V Schottky diode made out of a new material called Silicon Carbide (SiC) for one of our power supplies projects. Unfortunately, the answer at that moment was that there was no distributor in Europe that could supply that component.

Premium PSU was possibly the first Spanish company and one of the first in Europe to be interested in this new technology. After many inquiries, it was possible to find a supplier in the USA (at a 40€ cost) and finish the project. Thanks to the use of this new technology, we managed to outperform other power supplies manufacturers.

Premium’s power conversion system could deliver a higher peak power (30kW instead of our competitor’s 21kW) and was 25% smaller, as there was no need to use huge aluminum radiators due to the fact that improved efficiency made them unnecessary. This design was done for a major semiconductor machinery manufacturer and resulted in a huge benefit for Premium. Still today, 15 years later, it remains one of the Top Sellers of our portfolio.

But what is the secret of Silicon Carbide and what makes it so revolutionary in the design of power semiconductors?

The answer lies in the intrinsic properties of silicon carbide:

- Technology

- Breakdown voltage [kV/mmB]

- Thermal conduction [W/cm K]

- Si

- 30

- 1,5

- SiC

- 300

- 5

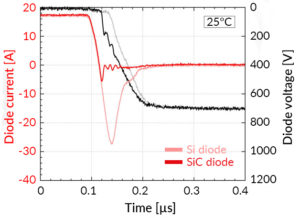

SiC Diodes

SiC diodes have a very small Reverse Recovery Effect, which reduces the switching losses, allowing to:

- Increase efficiency vs. design with Si diodes (if the same fs or switching frequency of the equipment is maintained)

- Increase the power density vs. design with Si diodes (if the same efficiency is maintained), as the equipment’s fs can be increased while reducing the size of inductive components

SiC MOSFETs

SiC MOSFETs offer the following advantages:

- A huge reduction in the specified ON-Resistance for applications over 900V, which allows a higher current density per device and a reduction in size and weight

- Less variation of ON-Resistance with temperature, which allows the design of equipment that works at a higher temperature. If the temperature increases 100ºC in the component (25ºC to 125ºC), the RDSon increases: silicon by a factor of 2 and SiC by a factor of 1.5

- A tremendous reduction in internal capacitance:

- The Reverse capacitance (Cgd) is almost non-existent

- An extremely high switching speed is possible

Furthermore, these semiconductors that enable faster switching require expert designers. This is because of parasitic elements that increasingly require greater consideration during the design process. The MOSFET SiC driver method is also more complex and requires a high degree of Know-how.

SiC Technology in our power supply solutions

At Premium PSU, we are aware that investing in this technology represents a competitive advantage and adds value to our products. This is why we have extended the use of SiC diodes to all of our solutions. We partner with SiC MOSFET manufacturers around the world, having preferential access to state-of-the-art design information, therefore allowing us to use new components in our products before they are released in the market.

Staying up to date with the latest news in the market and having the best engineering team for power supplies and conversion systems in Europe is what makes our designs be at the forefront of technology.

We are proud to be one of the first power supplies manufacturers in the world to use TO-247 1200V packaged SiC MOSFET in our designs. This new MOSFET, with a channel resistance of only 9mΩ, is absolutely revolutionary and somewhat unimaginable a few years ago, just like the first diode was 15 years ago. Again, at Premium we are at the cutting edge of SiC Technology, and this is one of the things that make our designs unique.