Success in Power Electronics Integration to Power HVAC in Trams

Our valued customer, a prominent manufacturer of HVAC systems for the railway industry, partnered with Jordi Ribalta, our Sales and Business Development Manager, to embark on a journey of engineering excellence.

Jordi Ribalta – Sales & Business Development Manager

This collaborative success story serves as a testament to our unwavering commitment to delivering excellence and pushing the boundaries of what is achievable in the realm of engineering and technology. Both companies have worked closely with the R&D and Commercial departments on a highly innovative project.

Product Application and Location

An HVAC (Heating, Ventilation, and Air Conditioning) system in a train or tram is an air conditioning system that controls the temperature, ventilation, and air quality inside the train or tram carriages. These systems are essential to provide a comfortable and safe environment for passengers and onboard staff.

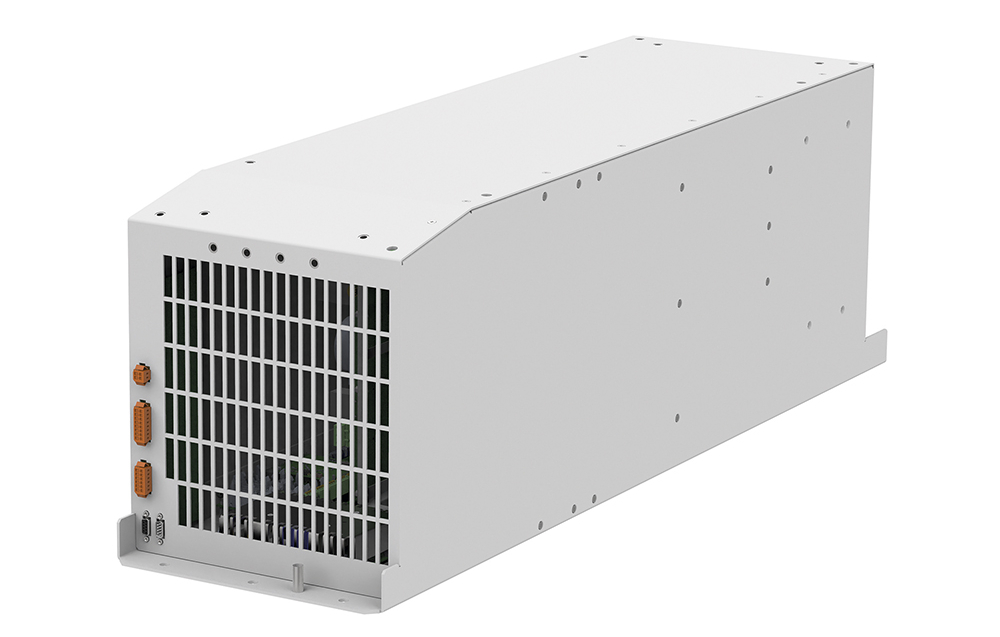

The project focused on creating a custom product design for the air conditioning system installed on the roofs of the new trams. The DC/AC inverter’s role is to convert power from the 750V DC overhead line into alternating current (AC) to power the compressors and heaters at 3 x 400V. More than 30 trains have been operating with this system since September 11.

Importance of Power Electronics

Power electronics play a critical role in the client’s product, enabling the HVAC system’s power supply. The innovation lies in an inverter that combines an active overhead line filter with a DC/DC converter using IGBT (and SiC in the inverter stage), achieving an efficiency of 92%.

SiC technology is a key innovation in power electronics that offers significant benefits in terms of efficiency, size, and operation capability under extreme conditions. As a power electronics manufacturer, Premium PSU uses it in a wide range of applications to enhance the performance and efficiency of AC/DC rectifiers systems and DC/AC inverters, among others.

Product Challenge and Requirements

The main challenge was to meet stringent requirements for dimensions, power, and weight. The inverter could not exceed 60 kg and had to fit within the client’s HVAC mechanics, resulting in a device with dimensions of 300 x 360 x 1100 mm. The required power was 40 kW, divided between two inverters, one of 35 kW and another of 5 kW, with independent control. Furthermore, it had to operate on 600V and 750V DC overhead lines, complying with the specific EN50163 regulations.

The EN50163 standard refers to railway electrification standards and establishes technical specifications for electrical power supply systems used in railways. It focuses particularly on protection against overvoltages and atmospheric discharges in railway electrification systems. These standards are crucial to ensure the safety and reliability of electrical infrastructure on railway tracks.

Choosing Premium PSU

The client chose Premium PSU due to competitive pricing, delivery time, and a strong trust in the company based on previous collaborations. This long track record of success in joint projects was a key factor in the selection.

This success story highlights Premium PSU’s innovative capabilities and expertise in integrating power electronics into railway transport applications, contributing to the efficient and sustainable operation of trams.