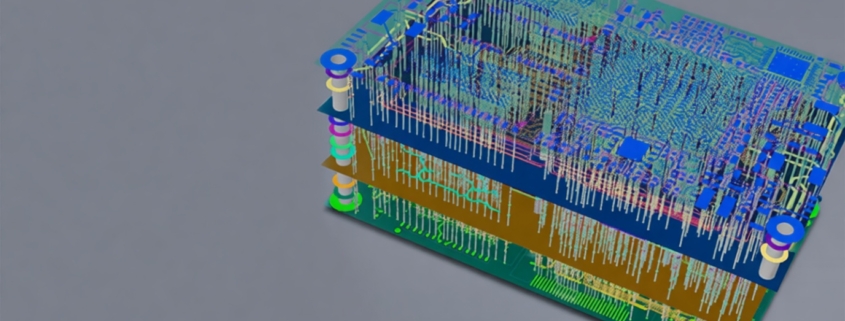

Why Multilayer PCB Design Makes the Difference in Power Electronics

In power electronics, reliability does not start with the schematic or component selection. It starts much earlier: with the structural decisions made at the PCB level.

Choosing between a single-layer, double-layer or multilayer PCB may seem like a minor detail, but in reality it defines the thermal behavior, durability and overall robustness of the system. Especially in demanding applications, the PCB is no longer just a mechanical support—it becomes a critical part of the design.

Why does multilayer PCB design matter?

In industrial, railway or energy environments—where most Premium PSU solutions operate—the PCB must withstand high currents, fast transients, vibration and severe thermal variations.

In this context, a multilayer PCB is not a luxury. It is a technical necessity.

A well-designed multilayer PCB enables:

-

Higher effective copper density, reducing series resistance and conduction losses.

-

More uniform current and temperature distribution, preventing hot spots that accelerate component and solder joint degradation.

-

Reduced return loops and electromagnetic interference (EMI), thanks to dedicated ground or power-return planes.

-

Improved mechanical robustness, essential in applications exposed to vibration, shock or continuous thermal cycling.

These benefits do not only improve short-term performance—they directly increase long-term reliability.

When does a multilayer PCB make sense?

Using a multilayer PCB is fully justified when:

-

High currents or frequent current peaks are involved.

-

The equipment operates in environments with vibration, humidity or wide temperature ranges.

-

The application requires long service life with minimal maintenance.

-

Electrical and thermal stability over time is critical.

In these cases, simplifying the PCB to reduce cost often leads to the opposite result: premature failures, unplanned downtime and costly rework.

The most common mistake when choosing a PCB

A frequent misconception is assuming that more copper or more layers automatically mean a better design. That is not the case.

Extra copper thickness or an additional layer, if poorly implemented, can increase cost without delivering real value. The challenge is not adding material, but properly managing current return paths, thermal dissipation and electromagnetic integrity.

In other words:

a robust PCB does not depend on copper thickness alone, but on the engineering criteria behind the design.

At Premium PSU, we see this every day:

-

A properly designed multilayer PCB prevents failures, downtime and rework.

-

A poorly designed one only adds cost and complexity.

That is why, before defining the PCB layout, we always analyze the full application context: nominal and peak current, operating environment, cooling strategy and power topology. Only then can we ensure that reliability starts at the foundation—within the PCB architecture itself.

Does your application operate under extreme or critical conditions?

Our engineering team can help you assess whether your current design is truly prepared to withstand them.

Contact us, and we will evaluate together the level of robustness required—starting from the PCB design itself.