Case Study Ensuring critical lubrication in wind turbines during grid-Out scenarios

A CBS-10K HV DC/DC–based approach to protect high-value mechanical assets

Ensuring Critical Lubrication in Wind Turbines During Grid-Out Scenarios

A CBS-10K DC/DC–based approach to protect high-value mechanical assets

Wind Energy Context

Wind energy plays a key role in the global transition towards renewable electricity generation.

Modern wind turbines are highly optimized machines, combining large mechanical structures with increasingly complex electrical and control systems.

Beyond energy production, asset protection during abnormal operating conditions—such as grid loss—has become a key design driver for wind turbine manufacturers.

In this context, short-duration but highly reliable backup power systems are essential to protect critical mechanical subsystems whose failure can lead to severe economic and operational consequences.

The Challenge: Critical Lubrication Under Grid-Off Conditions

One of the most critical subsystems inside a wind turbine is the lubrication system associated with mechanical orientation and positioning mechanisms operating under high load.

The application described corresponds to large onshore wind turbines in the ~7 MW power range and above.

In the application described, lubrication is directly linked to the yaw system and associated orientation mechanisms required to safely position the rotor relative to wind direction.

Yaw system lubrication

The yaw system is responsible for orienting the nacelle and rotor towards the wind direction.

It includes large bearings and gear mechanisms operating under very high mechanical loads.

Insufficient lubrication can lead to accelerated wear, severe mechanical damage and long turbine downtime.

These mechanical systems are high-value and difficult to repair, making lubrication continuity a non-negotiable requirement.

During grid-off scenarios, lubrication must remain active to:

- Avoid metal-to-metal contact

- Complete controlled shutdown procedures

- Protect mechanical assets with replacement costs ranging from tens of thousands to several hundred thousand euros

To address this challenge, a high-power DC/DC backup solution based on the CBS-10K converter was selected to guarantee electrical stability during grid loss.

Why Traditional Backup Architectures Fall Short for our Client’s wind turbines

Historically, backup solutions have relied on:

- DC/AC inverter-based systems with delayed switching

- Conventional UPS architectures

- Low-power DC/DC converters without dynamic overload capability

These approaches in our client system failed to meet the real needs of the lubrication systems because:

- Switching delays introduce voltage dips

- VFDs are highly sensitive to microsecond-level instability

- High inrush currents during motor startup cause voltage collapse

As a result, lubrication pumps may stop before the cycle is completed, exposing mechanical components to damage.

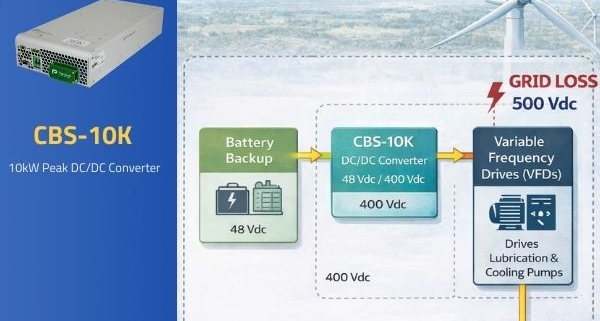

A DC/DC-Centric Solution Based on CBS-10K

To overcome these limitations, a DC/DC-centric backup architecture was implemented.

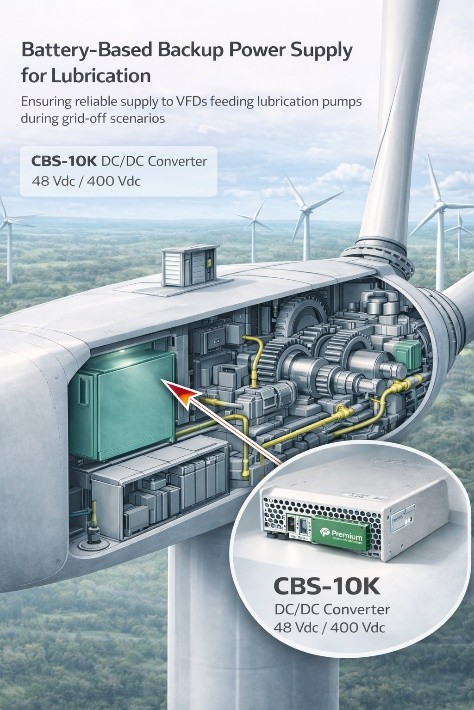

At the core of the solution is a CBS-10K DC/DC converter, acting as the power bridge between the battery system and the VFDs driving lubrication pumps and auxiliary motors.

Key design principles:

- Immediate takeover during grid loss

- Absolute voltage stability, even under high transient loads

- Short-time overload capability to support motor startup

- Compact and robust design suitable for nacelle integration

Rather than providing long autonomy, the objective is to guarantee completion of the lubrication cycle under all grid-off conditions.

System Architecture (Conceptual)

(Image placeholder: conceptual block diagram of battery-based DC/DC backup architecture)

Why the CBS-10K DC/DC Approach Works

The CBS-10K solution succeeds where other architectures failed thanks to:

- High power density

- Short-time overload capability

- Excellent dynamic response

- High tolerance to inrush current

- Industrial robustness proven in demanding environments

- UL certification readiness with only minor adaptations

Importantly, the solution is based on a standard industrial platform, minimizing technical and supply-chain risk.

Results and Operational Benefits

In operation, the DC/DC-based backup solution has demonstrated:

- Stable performance during grid-off events

- Elimination of unintended VFD trips

- Reliable completion of lubrication cycles

- Effective protection of high-value mechanical assets

- Reduced operational risk and avoided high-impact OPEX events

Onshore Deployment – Offshore Validity

The solution is currently deployed on onshore wind turbine platforms, including high-power turbines in the multi-megawatt (≈7 MW) class, where fast and reliable short-duration backup power is required.

This class of large onshore wind turbines is subject to strong market demand, with annual production volumes typically ranging from several hundreds up to around one thousand units per year, depending on market conditions.

From a technical standpoint, the same CBS-10K DC/DC approach is also valid for offshore applications, where similar stability and fast takeover requirements apply within the redundant system architectures.

Key Takeaways

- Lubrication continuity is mission-critical during grid-off events

- Electrical instability directly translates into mechanical risk

- In large onshore wind turbines, mechanical failures have a very high economic impact

- A battery-fed CBS-10K DC/DC architecture ensures fast and reliable backup power