Premium products like TDS-3300, TDX-3300, ODS-3000 or ODX-3000, which are designed to be cooled by internal fans, can also be mounted inside closed boxes, according to the following instructions.

This is possible because a significant portion of the heat generated by these products is conducted towards the top side, which allows to install a heatsink and to evacuate it to the outside of the enclosure or box.

The following instructions allow sizing both the box and the necessary heatsink.

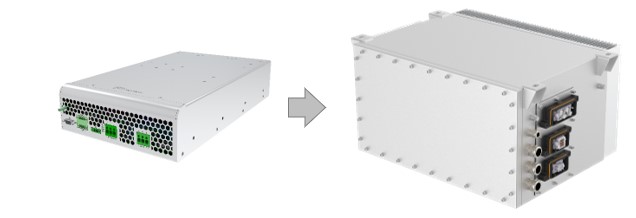

The size of the box should be large enough so that air can circulate around the product without difficulty. We have noted that 50mm of clearance is sufficient for the indicated products. See drawings below.

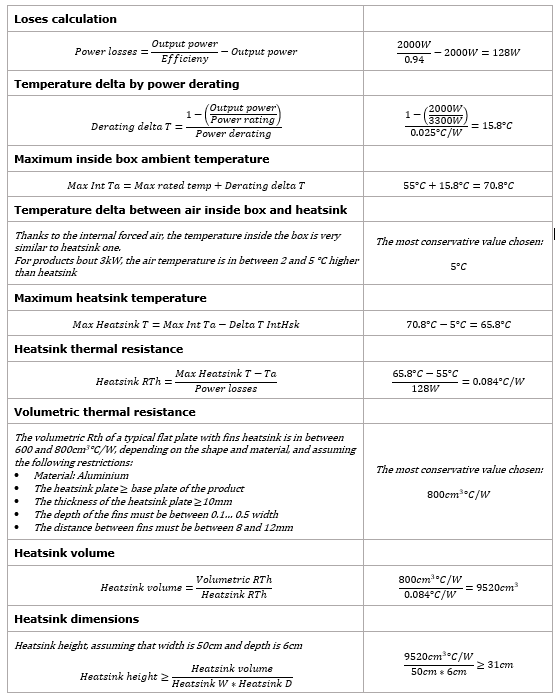

The thermal resistance of the heatsink and, therefore, its size, must be calculated considering the maximum loses of the product and the ambient temperature inside the case. It is also possible to estimate the heatsink size with sufficient accuracy using the volumetric thermal resistance method, since heatsink volume has a very linear relationship between volume and thermal resistance; see example below.

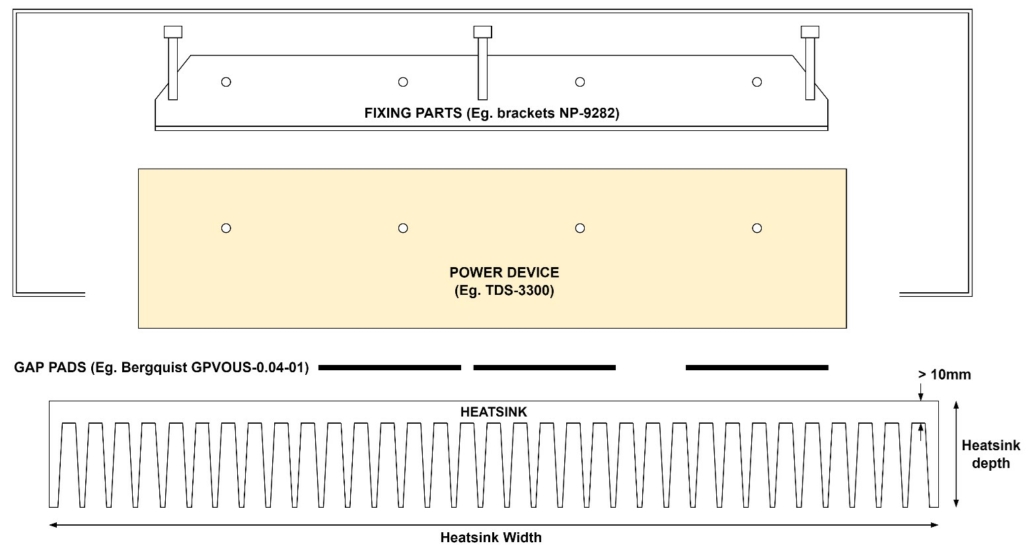

An important factor is the thermal coupling between the heatsink and the product. In our laboratory, the best results have been obtained by using separate pieces of 1 mm gap pad on the hottest surfaces of the product. A single gap pad for the entire product surface makes it difficult to adapt the gap pad to irregularities in the flatness of the heatsink and the product.

Gap pads positioning for TDS-3300 or TDX-3300

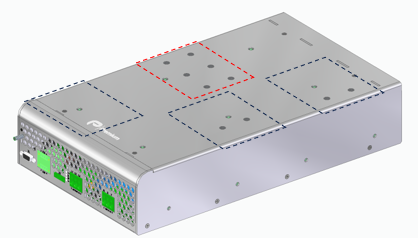

The pieces of gap pad Bergquist GPVOUS-0.04-01, or equivalent, of about 100 x 100 x 1mm, must be placed on the cover of the product (see dashed rectangles in the drawing below), where the internal heatsinks are in contact with the enclosure. It is possible to know the position of each internal heatsink by the screws.

The TDS-3000 only uses 2 of the 6 screws showed below (in red colour). However, the TDX-3300 model, with three-phase output, uses all 6 screws. The piece of gap pad placed on left corner it is only for balancing the pressure on the set once assembled.

Calculation example

Requirements for a TDS-3300

- Efficiency: 94%

- Maximum application ambient temperature: 55°C

- Maximum application output power: 2000W